News and Events

SNCR 7 MW

In 2022, BioEld delivered another SNCR system for ammonia to Jernforsen. The system will be installed 7 MW boiler in Norwegian Kirkenaer (Solör BioEnergi) for firing demolition wood chips. Commissioning will take place during the autumn.

During the autumn of 2021, BioEld delivered, installed and commissioned 2 SNCR systems for urea to Akershus Energi's two grate fired boilers in Lilleström (Norway).

SNCR 2 MW

An SNCR system for Urea was delivered in the spring of 2021 to AKJ. The system has been installed in a newly built 2MW frying pan in Töreboda (Daloc).

Conversion control system

In 2021, BioEld helped Norsk Energi to develop a function description with a new control philosophy in connection with the replacement of the control system for two smaller grate fired plants.

SNCR 10 MW

In the autumn of 2021, an SNCR system for ammonia was delivered to Jernforsen. The system has been installed in a converted 10 MW grid boiler in Tranås (Tranås Energi.)

SNCR 12 MW

In 2020, BioEld delivered an SNCR system for ammonia to Linka Energy. The system has been installed in a 12 MW grate boiler fired with straw in Slagelse (Denmark)

Retrofitting of flue gas recirculation

In 2020, a retrofit of flue gas recirculation was carried out in a 15 MW pellet-fired boiler in Köping (VME). BioEld assisted with systems and function descriptions, and helped with commissioning.

SNCR 4 + 5 MW

During 2019, BioEld has supplied 2 SNCR facilities for urea toThermokraft AS in Notodden Norway. They are installed in 2 boilers fired with recycled demolition wood (4 MW and 5 MW).

SNCR 5 MW

During 2019, BioEld also has delivered an SNCR system for Urea to Jernforsen. The system will be installed 5 MW boiler in Norwegian Tromsö

(Kvitebjørn Varme AS) modified for firing recycled demolition wood . Commissioning takes place during the autumn.

Uppdating boilers

BioEld is engaged by Akershus Energi to update their two wood chips fired boilers (Hollensen) in Akershus EnergiPark, Lilleström Norway. The work includes a new system solution and control philosophy for combustion air and flue gas return, as well as commissioning.

SNCR 4 MW

In 2017, BioEld delivered an SNCR system for Urea to Jernforsen. The installation took place in a new 4 MW steam boiler fired with wood pellet containing residues from the production of bio-oil. Property owners are Argent Energy.

SNCR 4 MW

Another plant for Urea was commissioned during 2017 in Arendal (Agder Energi) for 4MW boiler with cyclone burner for wood powder firing. The fuel is MDF briquettes.

SNCR 10 MW Demolition wood

In 2016, a SNCR plant (NH3) was delivered to a Jernforsen 10 MW hot water boiler fired with recycled demolition wood , which was commissioned in Elverum. Property owners are Eidsiva Bioenergi AS.

SNCR 25 MW forest residues

BioEld has in 2014 delivered an SNCR system to Tranås Energi. The installation took place in the new 25 MW power plant boiler fired by wood chips (forest residues).

In 2015, emissions of NOx averaged about 40 mgNO2 / MJ at the same time as low emissions of CO and NH3 slip (15 and 3.5 mg/MJ respectively) was achieved.

SNCR 25 MW Demolition Wood

In cooperation with the boiler supplier KMW Energi, a SNCR systems were installed in the newly constructed 25 MW power turbines boiler fired by demolition wood and delivered to Vetlanda Energi och Teknik . In addition to the machine delivery, BioEld contributed to the design of the furnace which is optimized for NOx reduction. The system was commisioned 2013.

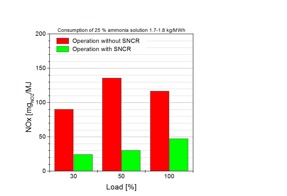

At completed performance tests have very low emissions of NOx was shown. NOx emissions were between 25 and 47 mg / MJ at conditions of NH3 slip <10 ppmvg before the flue gas (approximately 3 mg / MJ) and 1.7-1.8 kg / MWh consumption of 25% ammonia solution

BioEld was engaged by Jernforsen for project management in the construction of 2 separate boiler lines with flue gas condensation which became in operation in autumn 2016. The end customer is Täby Fjärrvärme, jointly own by Eon.

Project managment 15 MW grate firing with wood pellet

BioEld was engaged by Hotab for project management in the construction of a new 15 MW pelleteldad hot water boiler which became operational in autumn 2014. The end customer is Borås Energi och Miljö